EFNARC nozzle operator training

Shotcrete fundamentals and practical training for nozzle operators

The nozzle operator plays a crucial role in ensuring the quality of sprayed concrete. Acting in the contractor’s interest, the operator is responsible for the proper operation and maintenance of the equipment as well as for maintaining workplace safety. Recognizing the significance of nozzle operator training, EFNARC developed an internationally recognized certification and training program.

The Nozzle Operator Certification Scheme, delivered by recognized EFNARC examiners, was introduced in 2009. With the rapid advancement of modern robotic application equipment and new concrete technologies, the demand for specialized education and training has grown significantly.

The EFNARC Nozzle Operator Certificate establishes a standardized quality framework for training and assessment, combining theoretical instruction with practical experience, including the use of Virtual Reality (VR) simulator technology.

The certificate is awarded upon successful completion of the course and submission of proof of a minimum of 40 days of robotic spraying experience. Inexperienced operators are welcome to attend the training course and can return for assessment once they have acquired the necessary spraying experience.

Why is it worth sending your employees to the Nozzle Operator Training at Hagerbach?

- Wet and robotic spraying enhances safety for your employees. By using a controller, they can maintain a safe distance from the spraying area, reducing the risk of exposure to rebound and dust.

- Spray training at our site closely simulates real working conditions inside a tunnel. In contrast, other training courses held outdoors are too far removed from actual working environments.

- Training at the Hagerbach Test Gallery helps your employees work more efficiently, resulting in less material waste from rebound and overspray.

- Improved application techniques lead to higher quality and greater construction safety.

- When pursuing international business, an internationally recognized certificate can give you a competitive edge and help you secure contracts.

- The balanced combination of practical and theoretical training provides course participants with comprehensive knowledge to understand the various aspects of shotcrete technology.

- In Switzerland, companies with a Parifond membership are entitled to a 50% reimbursement of the course fees.

Next dates

Monday 16th to Friday 20th June, 2025

Monday 29th September to Friday 3rd October 2025

Additionally, the course can be booked at any time with a minimum attendance of two participants, as we now have the simulator permanently on-site.

Program

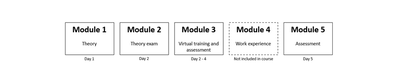

MODULE 1 – THEORY SESSION

Participants attend a full day of classroom-based theory covering both basic and advanced topics, including concrete and spraying technology, application methods, surface treatment and curing, testing procedures, and Health, Safety, and Environment (HSE) standards.

MODULE 2 – THEORY EXAM

Each participant completes an individual online theory exam consisting of 30 multiple-choice questions.

MODULE 3 – TRAINING AND ASSESSMENT IN VIRTUAL REALITY (VR)

Participants complete 10 predefined training scenarios and assessments using VR simulators.

MODULE 4 – WORK EXPERIENCE

Participants must submit documentation verifying a minimum of 40 days of spraying experience. This experience may be acquired either before or after the course. Only participants who have documented experience will proceed to the final assessment day.

MODULE 5 – ASSESSMENT

Participants undergo a practical assessment using a real spraying robot. This module takes place on day 5 of the course for those who have submitted proof of work experience. Novice operators will complete this module at a later date, typically at their own worksite.

Information

This EFNARC course is offered by the following providers:

- CAMPUS SURSEE (Swiss training centre for construction experts)

- CUC (Centre for Geotechnics and Underground Construction)

Educators:

- Certified EFNARC examiners and instructors

Course Fee: (incl. GST/VAT)

- CHF 4'945 without lodging

- CHF 5'445 with lodging

- Parifond members are entitled to a refund of 50% of the course costs.

- The costs include lunch, drinks during breaks and conference documents.

Included:

- Lunch, coffee, refreshments during breaks and conference documents.

- Theory lessons by CUC as per the guidelines from EFNARC.

- Registration in the database of EFNARC.

- Online theory exam.

- Simulator training and exam.

- Live hands-on spraying.

- EFNARC certificate once required word experience (module 4) has been gathered.

Not included:

- Dinners and beverages consumed outside Hagerbach Test Gallery.

- Transfer from and to the airport.

- Flights/travel

Venue:

- Hagerbach Test Gallery Ltd., Polistrasse 1, CH-8893 Flums Hochwiese

Registration:

- Kindly complete your registration using the form below at least two weeks before the course commencement date.

Payment:

- Payment of the course fee to CUC must be made according to the invoice details and completed before the course begins.

Cancellation:

Reimbursement in case of written cancellation by participant:

- 100% - 0-21 days before training

- 75% - 21-28 days before training

- 50% - 28-60 days before training

- 25% - over 61 days before training

Refunds will not be issued for missed training sessions or no-shows.

Should there be insufficient registrations, the course will be postponed with a minimum of three weeks’ notice.

Proof of qualification:

- Participants who provide proof of 40 days of spraying experience and successfully complete the course will receive an internationally recognized EFNARC Certificate (endorsed by ITA) at the end of the course.

- Inexperienced nozzle operators who have successfully completed Modules 1–3 may return to complete Module 5 once they can provide proof of the required minimum of 40 days of spraying experience. Alternatively, they may arrange with the examiner to carry out the practical assessment directly at their worksite once the necessary experience has been gained.